Construction & Fabrication

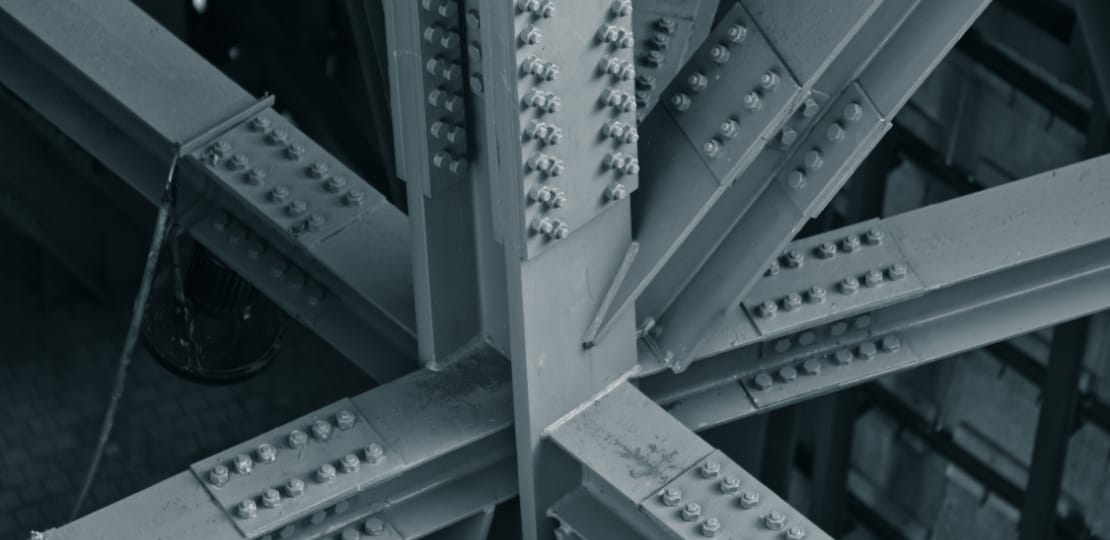

Construction and Fabrication Connects our World. Hobart® filler metal connects structures.

From small construction jobs, to large bridges and skyscrapers, confab welding projects demand high-quality welds — which means you need filler metals you can count on: Hobart® filler metals.

Poor weld quality hurts your projects — and your company.

Welding is critical to structural projects, so don’t compromise: Hobart provides superior weldability for a wide range of applications. From light construction and home fabrication projects to large structures like the San Francisco-Oakland Bay Bridge, Hobart has the solution.

It’s the tie that binds STABILITY + TRUST

Every day, 250,000 vehicles pass over the San Francisco-Oakland Bay Bridge. To ensure safe journeys, engineers responsible for the integrity of the bridge’s structural steel depended on Hobart filler metals — see why.

Products

Hobart® 418

AWS: E7018 H4R, E7018-1 H4R

Good general purpose low hydrogen electrode. Easy to use in all welding positions, with excellent arc stability, low spatter levels, and easy slag removal.

Fabshield® XLR-8 ™

AWS: A5.20: E71T-8JD-H8

For those applications requiring all position capability with low temperature impacts. Designed for use outside.

Fabshield® XLNT-6

AWS: A5.20: E70T-6

For applications that require a self shielded high deposition wire with low temperature impact toughness. Designed for use outside.

Fabshield® 21B

AWS: A5.20: E71T-11

This wire is used for almost any general purpose welding application and in any position. Works well on coated steels.

FabCOR® 86R

AWS: A5.18: E70C-6M H4

Higher deoxidization elements allow this metal cored wire to have more tolerance for mill scale welding applications

FabCO® RXR

AWS: A5.20: E70T-1C/-9C

RXR is an E70T-1 wire that has a higher level of de-oxidizing elements to handle mill scale, rust and other contaminants.

FabCO® Excel-Arc™ 71

AWS: A5.20: E71T-1C/M H8, E71T-9C/M H8

All position wire for both CO2 and mixed gas. For mild and low alloy steel applications.

FabCO® Triple 7

AWS: A5.20: E71T-1C/M H8, E71T-9C/M H8 A5.29: E81T1-GC/-GM H8

Intended for single and multiple pass applications in all positions. Designed for carbon and higher strength steels.